Forum Replies Created

-

AuthorPosts

-

Update: the wording of the answer is “Probably, but it depends on the model”

Hi Nickesh

The correct answer is something like “probably, but check the manual “ (I’m answering this from my phone, so I can’t look up the exact wording). If you look at the lesson, you should see that this makes sense.August 1, 2025 at 11:18 am in reply to: Front load washer drum support Module 3 unit 8 question 2 #27369Hi Ronald,

The correct answers are:

Broken drum support spider

Failed support shock/shocksHopefully that makes sense, based on what we cover in the first video in that unit. Let me know!

are there times where only the freezer compartment is calling for cooling so therefore the supply damper doesn’t open?

It follows from what Sam wrote that you can have situations where the fresh-food compartment is set fairly warm and the freezer is set to be very cold where the damper would stay closed.

Yes – but it isn’t a 10 ohms “connection” – it is the heating element. So the output of the 10-ohm heating element is about 5664 watts.

Hi Denis,

He did that using the same technique shown in the last video in Basic Electricity, unit 4 – finding the heat generated by a loose connection.

In the Appliantology post you are talking about ( https://appliantology.org/blogs/entry/1313-electric-dryer-keeps-burning-wires/) there is a 10-ohm element in the circuit. If we had a 0.1 ohm loose connection there would be Total Resistance of 10.1 ohms in the circuit.

Current in the circuit = I = E/R = 240/10.1 =23.762

Heat generated by the 0.1 loose connection = P = I^2 x R = 23.8 x 28.8 x 0.1 = 56 watts

Let me know if you have any other questions!

July 23, 2025 at 8:27 pm in reply to: Module 4 Unit 5 Voltage Drop w/series & parallel circuits #27350Hi Darci,

I’m glad to see you are thinking this through!

Voltage drop is the difference in voltage created across a load when current is flowing through it. In other words, if you put one of your meter probes on one side of the load, and the other probe on the other side, that voltage measurement would be voltage drop.

For this scenario, the voltage drop across R1 is 142v.

The sum of the voltage drops will equal the source voltage, so if 142v is dropped across R1, that means 240-142=98 volts will be dropped across the parallel circuits.

So, it is not accurate to think that 142v is “left” after R1. It is more accurate to think that 142v is “used up” by R1, leaving 98v for Req, although that’s not a perfect way to think about it either.

(My view: Power=240V—->First Load–>–142V–> Parallel Circuit—> 98V—> Neutral)

Remember that there is no neutral line in a 240v circuit. It is L1-L2. Also, this is alternating current. You have electrons moving rapidly back and forth in the circuit (it’s actually like a vibration, it is so fast). So be careful thinking of this in one direction like you sketched out there.

That is why I don’t like to think of the voltage as being “used up”, but that the voltage drop is created by current flowing through a load (E = I x R).

You’ll continue to review this and hopefully it will clear up as you go along.

Let me know if you have more questions!

Hi Steven,

Did you see the Video Player Controls page? We link to it under the first video in the course (Mod 2, unit 2 – “IMPORTANT VIDEO TIP”)

https://my.mastersamuraitech.com/video-player-controls/

Every original MST video in the course has a searchable transcript.

The intention is that students treat videos as if they are in a classroom. Meaning, paying attention and taking notes. The nice thing is that you are in control of the video. You can adjust the speed up and down, you can pause to take notes, back up to re-listen to a portion, etc.

Your notebook should have a page (or more) for each unit in the course where you list the video(s) and topics covered in it. That becomes a reference for you when you want to go back to find a particular discussion.

Most of our students want more videos, not fewer, which is unfortunate for the occasional student who would prefer to have more text.

There are no reading assignments in the Kleinert book until Module 4. You’ll see them listed in some of the units.

I did! Just replied.

Hi Danny,

Unfortunately it is too big of a file to email (56 MB) so some kind of drive has to be used.Hi Blake,

The answer is “power and control”.

There’s a lot of info in Unit 7! Including this section:

In general, the two types of voltages you will measure (aside from AC and DC) are:

– Power voltages: these are used to drive the loads that do the appliance’s work– motors, heaters, lights, etc. These are usually AC line voltages.

– Control voltages: these are uses to control power voltages. Examples are digital data logic lines. These are usually DC voltages.

Hi Lucas,

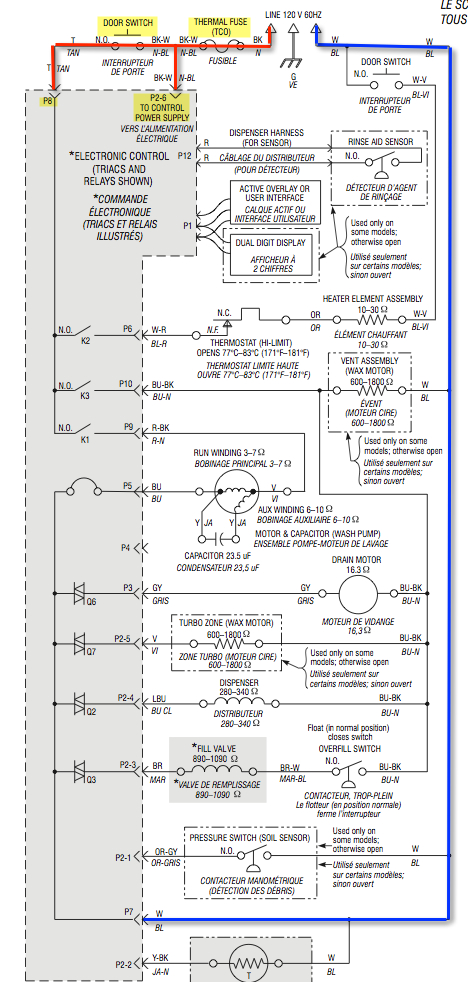

Is this for Unit 4, the image that goes along with the audio clip? If so, it showed up for me, which suggests you might need to refresh your browser, maybe clear your cache, etc.Here’s the image- does it work for you?

No worries!

Questions are always encouraged and welcome! When there are a number of them, it may just take us a bit to get our reply together 🙂

-

AuthorPosts