Forum Replies Created

-

AuthorPosts

-

Hi Darren,

Good question, and you’ve basically got it correct.

The Ribbon connector (from the low voltage board) provides the power to energize the coils in the relays, which creates a magnetic field that closes the switch(es). When a switch closes, that provides L1 up to a load. (Neutral is connected to the other side of the loads.)

Just a couple of other things to make sure you’re thinking of it clearly:

When you think of L1 “flowing” through the switch, make sure you are thinking current (electrons moving). (Voltage does not “flow”.) Also, since this is AC power, the electrons will move back and forth through the switch, not just in one direction.

Make sense?

Hi Chase,

For Question 2, look for a little table on the tech sheet that’s titled “Temperature Switch Circuit” (it’s kind of in the middle of the sheet).

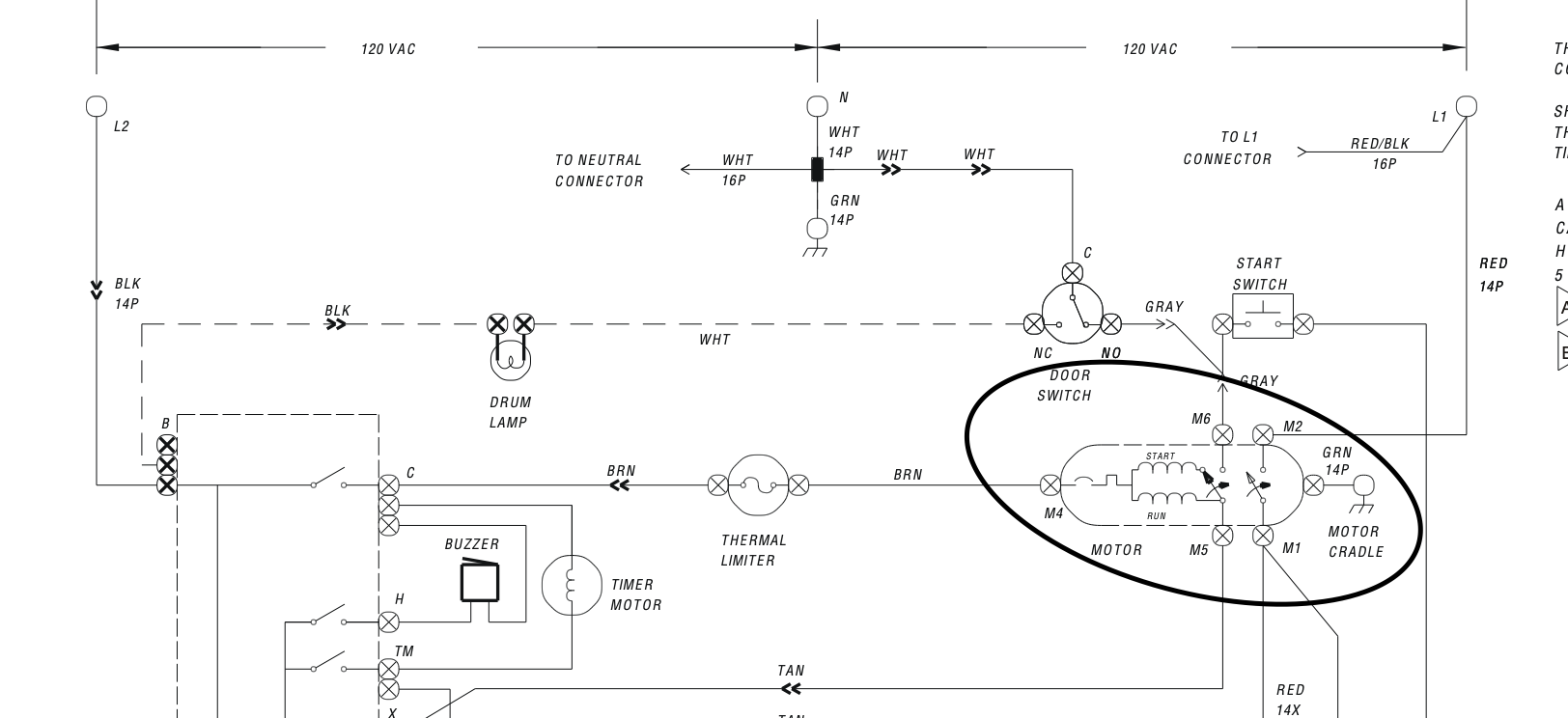

For #10, here’s a close-up of the schematic to make sure we’re looking at the same load. What do you see coming in to either side of the motor?

you’re welcome!

You want to look at the diagram labelled “Schematic Diagram” at the top, not the “Wiring Diagram”

On that schematic diagram, the lights are called “Hot Ind Lights” and the LOI is the one labelled LF-Y.

As you correctly answered on a previous question, there’s a yellow wire on the L1 side of the light, and red on the L2.

For Question 2, we ask how the light gets L1, and there are two correct answers out of the choices we give you. After you took the quiz for the first time, we also gave you the following tip – did you see this?

When the surface element is first switched on, the light gets L1 through the L1 to H1 contacts of the infinite switch and the black jumper wire. This can be easy to miss because the two ends of the black jumper aren’t explicitly shown as being connected.

During the element’s operation, once it gets hot enough, the light’s bimetal switch closes, providing another path for L1. This means that even after the infinite switch is opened, turning the element off, the light stays lit until the element cools off enough for the light’s bimetal to open again.

As for Question 3, how it gets L2 – that’s pretty straightforward if you look at the schematic and not the wiring diagram.

VDCs are old technology, found in radio transmitters and the old cathode ray tube TVs, for example. The only common application at this point where you’ll encounter it as an appliance tech is in microwaves.

There is still a transformer in this circuit, which steps up from line voltage to about 2000vac. Since power in has to equal power out (minus heat losses) in a transformer, the transformer is what determines the current (since P = I x E)

If you have any other questions, let me know.

Hi Ed,

Most people struggle with this question when they are looking at the wrong light on the schematic. You are looking for the Left-Front hot indicator light on the schematic. It is one of 4 lights (one for each burner).

How is the light you are looking at labelled?

I think if you go on and read the next bullet point, it’s clearer. The capacitor and rectifier work together to approximately double the voltage. We don’t go into detail about how that happens, we just want you to have a functional understanding of how these components do what they do. FYI – It is called a Voltage Doubler Circuit in the industry. This happens because the rectifier prevents the capacitor from discharging every half cycle, which is how the charge is roughly doubled in the capacitor.

Hi Rodney,

Heat can be used as a source of ignition, but not all heat will cause ignition. That’s why our answer “heat, oxygen, and fuel” is not correct.

Yes, oxygen is necessary, but we’re talking about fuel ignition in residential gas appliances – oxygen will be present! (Maybe one day when there are appliances in space we’ll have to be more specific 😉

So, of the three answers we give you, “good fuel flow and ignition” is correct.

Not a waste! We’re always happy to help. This is a tricky one for many.

Yellow is correct, but not black. Are you looking at the “Hot Ind Lights” now? You’ve got yellow on the left (L1) side of the LF light. What is the color coming from L2?

No – that’s not it. That’s a light that comes on when any of the burners are hot. We’re looking for the light that is specifically for the left-front burner. There’s a set of 4 of these lights…

Hi Chase,

This one can be a little tricky. First let’s make sure you’re looking at the correct load, because there are multiple lights. How is it labeled on the schematic?

January 26, 2020 at 12:14 pm in reply to: How to use voltage measurements in electric dryer won’t get hot #18228The Midterm question on the dryer is more about understanding voltage, current, and power in a circuit than it is about how to troubleshoot a dryer. Remember – the Midterm is right after the Basic Electricity module.

We tell you in the problem statement that the element has continuity, so you know it isn’t open.

We then want you to look at the measurements in Figure 1 and let us know what that tells you about voltage, current, and/or power in the circuit, and the general fault that is preventing the element from heating.

We show you 0 volts from L1-L2, across the element, but 120vac from each side of the element wrt a neutral point.

What does this tell you about what is (or isn’t) happening in the circuit to power the load?

Good job, Mike. This shows that you have learned a lot of the principles that you need to know in order to decipher any schematic. You already know more than the majority of techs out there (we know – we have been dealing with them for years!). Our courses are about teaching principles and giving a few examples to help. As you go out there and apply these principles to the schematics you encounter (both in real life and online – in our webinars and YouTube videos), you’ll continue to grow in proficiency.

Hi Ed,

Good question. The convection and bake elements are in parallel, not series. The configuration you see there for the red wire is called a daisy chain. It is helping to supply power to both elements, but is not causing them to be in series. You’ll often see daisy chains in the burner switches for an electric cooktop, as well.

And I’m glad that you know the convection element isn’t a switch! 🙂

-

AuthorPosts