Forum Replies Created

-

AuthorPosts

-

There are a few things that could cause inconsistent readings like that.

One would be if you have not isolated the component you’re measuring from the circuit. This is done by disconnecting one side of the circuit. This prevents backfeeding, which can compromise your measurement.

Another possible cause is simply poor contact with the measurement points. Unless your leads are dead on, you’ll get varying readings on your meter.

And yet another cause would be if you were measuring a component or circuit with reactive qualities, such as if there’s a capacitor in the circuit. Since your meter is actually sending a small amount of current through the circuit when it measures resistance, reactive components can mess with the reading.

Your takeaway should be this: ohms measurements are sometimes useful, but they are one of the least reliable measurements that your meter can do. The only time you should draw a diagnostic conclusion from ohms is if you measure that the component is completely open when it should not be. Any result other than that simply tells you that you need to proceed by using a more reliable and informative measurement, such as volts or amps.

May 28, 2020 at 8:32 pm in reply to: Basic electricity module 5 schematics unit 4 troubleshooting part 1 last video #19172I wanted to get a better understanding why when testing pin 8 to pin 6 that’s line why it’s 120 volts even if there was a drop across the load.?

I didn’t see where in the video he did that measurement — could you give me the timestamp?

I think the best way for you to get a better grasp of why he did those measurements and what they meant would be to watch the original video he was referencing. Give it a watch and see if it makes sense — write me back if you’re still confused about anything!

It does sound counterintuitive, but it has to do with how those inlet valves are designed.

When these inlet valves close, they actually take advantage of the water pressure to keep their sealing plungers closed. There is a small spring that pushes the plunger down, but it’s not strong enough to make a tight seal by itself. The engineers designed it so that with the valve closed, water can fill the space above the plunger and exert pressure on it. At least 20 PSI of water pressure is required to make a reliable seal.

Again, the pump does not run at all during agitation.

A small clarification on this, actually. In models where you have a pump that is physically attached to and run by the drive motor, the pump is technically spinning during agitation. But since it’s not spinning in the correct direction to pump water, it’s not actually accomplishing any work. It’s neither draining water from the tub, nor is it moving the water around in the tub. But technically it is moving, because it’s physically attached to the drive motor.

But you don’t mention that there even is a water pump that is doing anything during the agitation section.

Correct — because the pump doesn’t run during agitation. Water and clothes get circulated during agitation by the rotation of the agitator, which is turned by the drive motor. The drain pump only runs when the washer needs to drain water from the tub.

When we say, “On some models, the main drive motor drives the pump by spinning in the opposite direction than it did during the agitation cycle,” we’re saying that the drive motor spins in the opposite direction than it did during agitation, and that’s how the motor drives the pump. Again, the pump does not run at all during agitation.

Yep, that’s correct!

Yes, there are both refrigerators and freezers that don’t use evaporator fans. Common examples are mini-fridges and chest freezers. They use an evaporator plate and natural air movement to disperse the cold.

We’re talking about doing a resistance measurement here — that’s how you test a capacitor with an analog meter. And on most analog meters, 0 resistance is over on the right, with infinite resistance on the left. The needle’s resting position is at the left, on infinite resistance.

So when you first put your leads on an uncharged capacitor, it will first go to the right, reading low resistance. Then, as the capacitor charges from your meter, its resistance will get higher and higher until it becomes infinite.

Make sense?

Sorry it took so long to get back to you! But I do have an answer regarding your question about the thermally controlled switches.

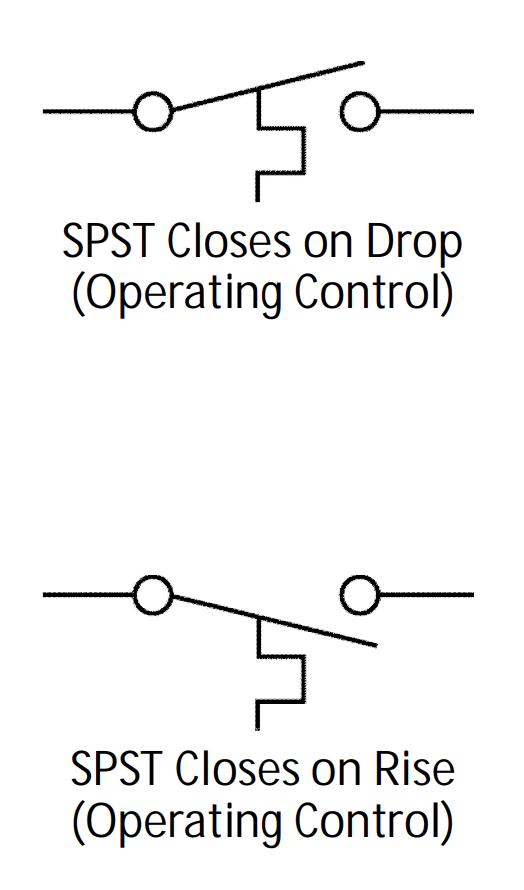

By convention, that squiggly thermally controlled symbol is always drawn below the switch. The thing that indicates how the switch responds to temperature change is actually the position of the switch itself. See the figure below:

So yes, you are correct that the switches as drawn on the schematic run counter to the convention. Flub-ups like this, especially on the finer points of schematic notation, are pretty common on manufacturer schematics, which makes it even more important for you to have a functional understanding of how the various components in appliances work.

Good spot!

The start device is part of how the control runs the compressor, but it is not part of the compressor itself. It’s a separate component. Therefore, it is not part of the sealed system as we define it.

Your neutral could be totally disconnected from the circuit and would still measure as a potential difference between it and L1.

That’s actually not true. If you use a loading meter (as we always say to do for AC measurements) to measure lime with respect to a floating wire like you’re describing, you won’t read 120 VAC. You would in fact read 0 VAC. The loading meter passes current through a circuit, and as you know, current cannot flow in a 120 VAC circuit without a valid neutral. The meter detects that no current is flowing and reports that you have no electrical potential between the two points.

The FF compartment would be the first to warm up. This is because the air movement provided by the evaporator van is vital in moving cold air from the freezer into the FF compartment. With the evap fan not running, the FF will warm up relatively quickly. It will take a bit longer for the freezer to warm up, since the evaporator is in the freezer compartment.

There’s a bit of a difference between a thermistor and a thermostat, yes.

A thermistor refers specifically to a device whose resistance changes with temperature.

The term “thermostat”, on the other hand, is used more generally to refer to any device that reacts in some way to temperature change. Oftentimes, manufacturers use the word thermostat to refer to a bimetal, such as a defrost thermostat in older types of refrigerators.

You’re correct about the voltmeter! You would read 0 volts, because there would be no voltage drop between the two points of measurement.

With the ohmmeter, keep in mind what OL means — it stands for overload, which means that the component being measured has more resistance than the meter can accurately measure. OL is what you read when a component is completely open. A short means that a component has 0 or almost 0 resistance, just like a wire.

When a component that normally has some resistance fails in such a way that it has much less resistance than it should, that is called a short. “Dead” here is just added for emphasis — a dead short is a short where the component has the same resistance as a strand of wire.

With that in mind, what would you read across a shorted component using an ohmmeter? What about with a voltmeter?

-

AuthorPosts