Forum Replies Created

-

AuthorPosts

-

Hi James. Different manufacturers do them differently. But here’s a video that explains the technology of the actuator used in the Whirlpool VM washer that you will find helpful: https://www.dropbox.com/s/6ahxishbereba4j/Whirlpool%20VMW%20F7E1%20Discussion%20Video.mp4?dl=0

Think about the load (heater) functionally. In other words, what does the heater need in order to function? It needs Line and Neutral, right? We see from the schematic trace that Susan posted for you that the heater gets Neutral at pin 1. Therefore, applying our knowledge of loads and circuits, we can deduce that heater pin 2 must get Line. Looking on the schematic, there is only one place Line can come from to supply to the heater– CN1-3 (3P-3). So one way you can tell is by applying circuit mojo and reasoning through the problem.

The other way is to look at the detailed photo of the main PCB on the Fast Track. You’ll see a connector there called out as CN1. This is the connector in question on the schematic (3P). You’ll see the pinouts for CN1 labelled as AC1 on pin 1, AC2 on pin 2, and AC2-1 on pin 3. We know from the schematic that AC1 on pin 1 is Neutral. We also know that AC2 on pin 2 is Line. We can infer from the labelling that AC2-1 is a *switched* AC2. So the board is taking Line on AC2 (pin 2) and *switching it* (via a relay) to AC2-1 on pin 3.

Thanks for your comments, Lamar. If someone is installing a dryer vent professionally (getting paid for it), then they should be aware of local codes as well as the manufacturer specifications. The course is aimed at repair techs, not installers, and vent specs mentioned in the course are taken from manufacturer specifications, not codes. But those manufacturer specs will often reference compliance with local codes so it’s worth noting that in the course.

As a tech, your main interest in a dryer vent is:

1) Is the back pressure within manufacturer specifications? This will usually be given as a range of air flow CFM at the exhaust. Here’s an example of manufacturer dryer vent specifications:

https://appliantology.org/files/file/7782-dryer-venting-specifications/

2) Does the dryer vent material present a fire hazard that the tech should point out to the customer?

Here’s a good webinar recording to watch showing how to troubleshoot a dryer with a slow dry complaint (which is usually caused by an out of spec vent): Click here

July 21, 2021 at 4:31 am in reply to: Kleinert vs. Samurai – taking the path of least resistance is futile #22369Good job paying attention! The Kleinert book is a useful reference with helpful and practical illustrations for some concepts but is not a very good text. I use it to give another angle and illustrations for some concepts. But for technical explanations, use the course material as your mainstay. The Kleinert book has several “tech myths” in some of its “explanations” of circuits. Another example of this is his explanation of how a control board reads the voltage drop across a thermistor. When you see these discrepancies between his explanations and the ones in the course, just ignore his and go by the one in the the course. If in doubt, always feel free to post a question here in the forum.

The purposes of jumping a switch is to see if it was preventing a complete circuit from being formed.

The purpose of cheating a load is to see if the load is capable of operating with a valid power supply.

Am I understanding this correctly?Exactly right. You have snatched the pebble from my hand!

Voltage supply is a cause, voltage drop is an effect of work being done in a load. Kirchoff’s law tells us that the sum of voltage drops in a circuit will equal the supply voltage.

Correct!

We would measure voltage supply because P=I*E. E meaning “electromotive force” aka voltage (supply). If we want to solve for P, we need the values for current and voltage

We measure voltage supply to make sure the appliance is being provided with a valid supply as specified by the manufacture. Without a valid voltage supply (meaning the correct amplitude and capable of sustaining current), it makes no sense to troubleshoot “inside the box” without first having the voltage supply corrected.

We would measure voltage drop to ensure the load is working as designed.

Good but keep in mind that some loads are electromechanical (like motors and relays) and, as such, have two failure modes: electrical and mechanical. For example, a motor with a jammed rotor will still read the correct voltage drop across the winding. But if the rotor is jammed or stuck, it will not operate correctly mechanically. An amp reading will pick this up, though, because the winding current in such a motor will be much higher than normal operating current.

If we did not measure 240VAC, (Say 220 VAC for example) then that would be an indication of the existence of resistance elsewhere in the circuit when there should not be.

Be careful with this. Most 240 VAC loads will still operate just fine on 220 VAC. The better way of discerning if there’s an unintended load in series with the intended load (eg., high resistance connection in series with a heating element) is by measuring amps and supply voltage then comparing the amp reading with the wattage rating of the load.

Example: A 240 VAC heating element is rated for 5600 watts @240 VAC. From this spec, you know the expected current reading would be about 23 amps. You measure the supply voltage and it’s 232 VAC. You measure amps and you read about 22 amps. Is the element in spec or not? How can we tell given the variance of the supply voltage from the specified voltage?

Set up a simple ratio:

23 amps / 240 VAC = X amps / 232 VAC

Solve for X:

X = (23 amps x 232 VAC) / 240 VAC = 22 amps

Conclusion:

The element is operating in-spec after accounting for the variance in the voltage supply.

(L1 to L2, should read 240 VAC right?)

Correct. And each Line to Neutral should read 120 VAC.

you said to measure voltage supply, not voltage drop.

Pop quiz:

– What’s the distinction between voltage supply and voltage drop?

– Why would you measure voltage supply?

– Why would you measure voltage drop?What process would you use to measure voltage drop across the element?

I would use the schematic to identify convenient EEPs and make both the voltage and current measurements there. Pro tip: if you use EEPs, you usually do not need to make the measurement directly at the component. You can usually do these measurements from a convenient location like the timer or control board.

Current = movement of electrons

Voltage is the cause

Current is the effect

In AC, the voltage is switching polarity 120 times per second. Current does likewise.

If a motor has a start winding, it is a single phase motor.

This is always true

If a motor has a capacitor, it is a single phase motor.

This is mostly true but cannot be used as a universal slam-dunk. Although three-phase motors do not need a start capacitor, you may see a run capacitor used with them for what’s called power factor correction. Usually this is only in on very large three phase motors used in industrial applications.

The best, most reliable way of telling what kind of motor you’re dealing with is to read the name plate on the motor itself. Or read the schematic.

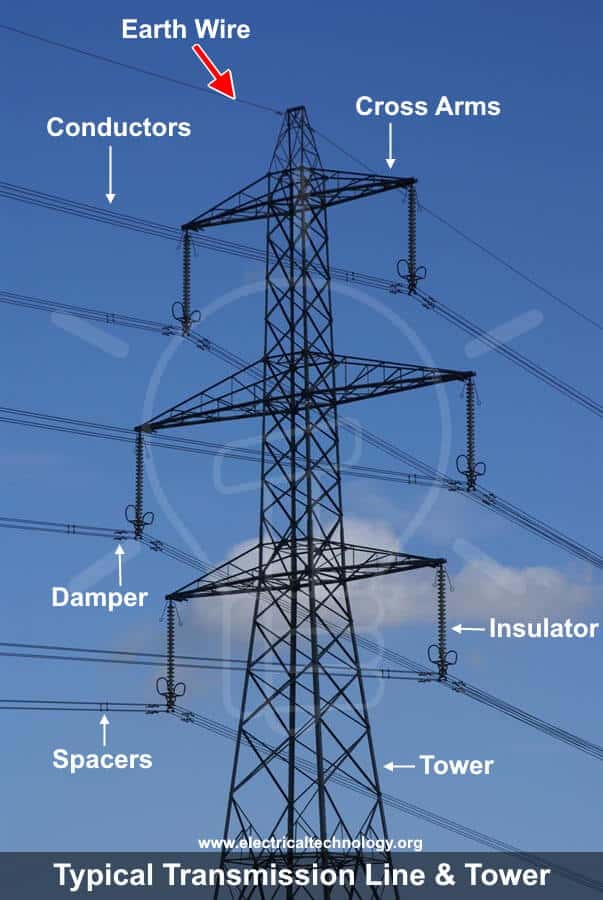

Excess electrons can build up due to static electricity (among other causes). In power transmission lines, lighting is a big concern and the transmission lines need to be protected from that.

In power systems, the ground wire is provided in overhead transmission lines having voltages of 110kV and above. In modern power systems, there are two ground wires on transmission tower instead of single for better protection.

The same question for basic circuits that are grounded.

In appliances, it’s the chassis that’s grounded. The power supply for loads will be either L1 to L2 or Line to Neutral (depending on the load). You’ll see this on the schematic for any appliance you look at. Ground is not part of the actual circuit for the load. In fact, the grounding conductor should never have current under normal operating conditions. Electrons move in the grounding conductor only when something has gone horribly, tragically wrong.

Without any voltage polarity in a circuit– which we call voltage difference between two points– electrons will not leave the copper atom they are attached to. Electrons cannot move on their own. There needs to be a voltage difference to make the electrons leave their atom and move to the more positive polarity.

The electrons will “change directions” based on the polarity at any point in time. In AC, the polarized line is changing polarity 120 times a second (two polarity flips per cycle, 60 cycle per second). Electrons are negatively charged and are always seeking the relatively more positive charge. The polarity of Neutral is zero all the time and does not change.

So when Line goes into the positive half cycle, Neutral looks negative to the electrons relative to Line and electrons will move in the Line direction. When Line goes into its negative half cycle, Neutral looks positive to the electrons relative to Line and electrons will move in the Neutral direction.

In DC, the polarity does not change with time so electrons are always moving through the circuit from the negative terminal to the positive terminal.

Electricity always works the same way regardless of the circuit configuration, whether it’s single phase or polyphase. Split phase is simply a special type of single phase.

Synchronous motors can be either AC or DC. AC synchro motors are ubiquitous in appliance repair: timer motors, damper motors, augur motors, drain pumps, etc. I have never seen a DC synchro motor in appliances. They do exist but are use in other applications. So the reference to synchro motors in the family tree is to AC synchro motors.

Motors work by electromagnetic forces. The changing voltage in the stator windings causes electrons to move which creates a changing magnetic field in the stator. This changing electromagnetic field in the stator causes electrons to move in the rotor. These moving electrons in the rotor then create their own magnetic field. When the pole induced in the rotor is the same as the pole in the stator (North or South) these similar magnetic poles will repel each other (opposite poles attract; similar poles repel). These poles are continuously changing with time 120 times a second (60 Hz power supply) and so the process continues throughout the revolution of the rotor.

There’s a blog post with videos that explains this in more detail. Watch both the excerpt and the full webinar recording: https://appliantology.org/blogs/entry/1191-how-magnetic-fields-in-a-split-phase-motor-work/

-

AuthorPosts