Forum Replies Created

-

AuthorPosts

-

Good! Just to summarize the operations inside an inverter:

AC–> Rectification to make DC–> Voltage “doubling” to higher DC–> 6 IGBT switches send DC through the three motor windings, changing polarity over time (this is the “inverter” process, making “AC on the fly”)

So I thought that the inverter was supplied with DC from the main control board and converted it to ac to power the motor by using 6 switches. What is actually happening is that the inverter board receives ac voltage, converts it to DC voltage and then back to ac to drive the motor?

There’s another step in that process that you’re missing. The inverter’s working voltage is 120 VAC. It takes that AC and does a couple of things with it: rectification and “doubling.” I say “doubling” in quotes because I’m referring to the general circuit process, not an exact numerical doubling.

The amplitude increase of the rectified voltage will vary according to the PWM control signal– it specifies to the inverter both the amplitude of the voltage to supply the motor winding with and the frequency of that voltage.

The frequency is controlled by how fast the 6 IGBTs switch the DC voltage through the motor windings. Since the current through the windings changes direction over time in accordance with then switched polarity of the supply voltage, this is alternating current in the motor windings. All because of those 6 switches. Think of it as making AC “on the fly.”

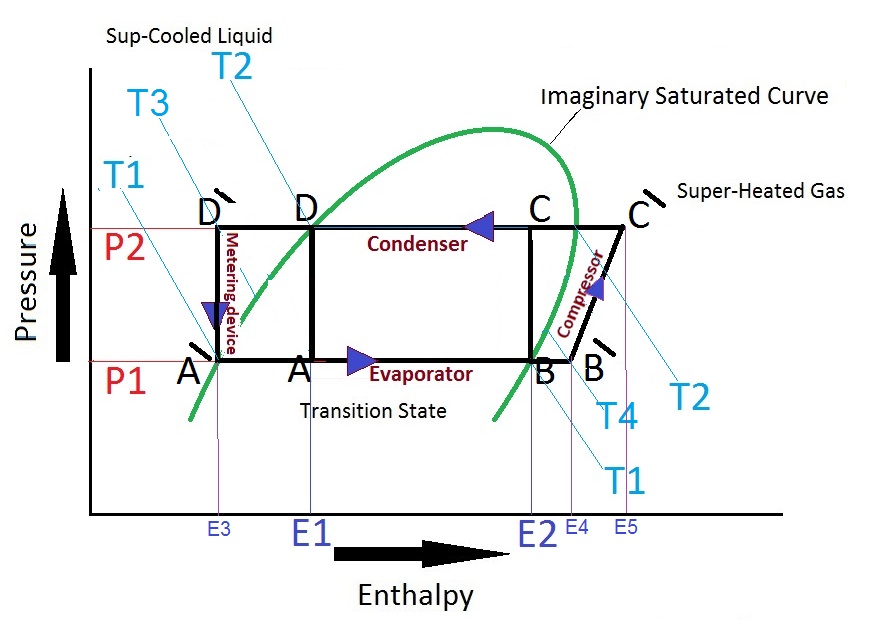

This simplified P-H diagram may help, too. It is idealized in that it ignores pressure drop due to friction in the tubing. But you’ll notice that in the superheating and subcooling portions pressure does not change. The only things that change pressure in the system are: the compressor (big increase), the transition from the capillary tube to the evaporator (big decrease) and friction in the tubing (negligible decrease). This is why I like the P-H diagrams– all this is clear at a glance. So the pressure measured at the low side gauge would be a pretty good approximation of saturation temperature assuming that pressure drop due to flow friction was negligible.

First off, recognize that the voltage supply for the thermistors is 5 VDC, not 120 VAC. The other thing to know is that the thermistor is part of a voltage divider circuit. There’s another resistor on the board in series with the thermistor. This is not shown on the schematic because as techs, we’re just interested in where the thermistor connects to the board so we can make our measurement. The CPU is measuring the voltage dropped across the thermistor. This image may help you see what’s going on “behind the scenes.” Voltage divider circuit used with thermistors.

Would that be the same case for module 5, unit 5, second video when half splitting?

Yes. Shhhh, don’t tell anyone! 😉

So, on the schematic with the jazz board, in the video the voltage is going from line one through the fan and back to the board to neutral.

Just a touch up here– Voltage doesn’t move around the circuit. We say that it is present or not present. The only thing that moves in a circuit is electrons (current).

Like how does the the compressor, condenser, and defrost heater get power?

The way to answer your own question is to look at the load of interest (eg., compressor, etc.) and how it connects to the side of the power supply that you can trace on the schematic. Then you know that the other side of the load that connects to the board is being switched by the board. So, for example, if one side of the load is hard-wired (unswitched) to Neutral, and the other side connects to the board, then you know that the board is switching Line to make the load run. Simple as that.

Also, when Samurai used a loading meter to test this in real life and the fan went from not running to struggling to run, is that because the loading meter technically completed the circuit?

Exactly right! Very good. The input impedance of my meter on LoZ is about 3K-ohms. So in that circuit, my meter was acting as a load in series with the intended load (evap fan). Some of the line voltage was dropped across the fan, and some across my meter. Since the fan was not getting full line voltage, that’s why it sounded like it was struggling.

I did that deliberately to see if students would catch it. Nice job!

There is no video so far going over this and I am very confused by it. When would that be needed. Also why?

Jeffrey, check out this video showing what ghost voltage looks like on your meter.

October 8, 2020 at 5:25 pm in reply to: Bonus Unit: Permanent Split Capacitor (PSC) for the Whirlpool Vertical Modular W #20281Thanks, Ronny. I’m always lurking and occasionally swoop in when I have some fun facts to know and tell. 🙂

October 8, 2020 at 6:39 am in reply to: Bonus Unit: Permanent Split Capacitor (PSC) for the Whirlpool Vertical Modular W #20273Evaporator and condenser fan motors in refrigerators will either be shaded pole or BLDC motors. Neither require capacitors.

Actually, looking at that circuit again, the valve get Line voltage through a triac. So if the coil failed open, the triac would not be conducting. The input impedance on the loading meter may or may not be low enough to allow anode current through the triac, depending on the meter. 3K-ohms is usually low enough for most triacs used in appliances.

if the cold water valve were to fail instead of the drain pump, why would you measure 0 VAC between VCH7.1 to VCH7.3? I thought i should measure 120vac because the cold valve circuit is open and there should not be any voltage present at VCH7.3.

That’s a great question! I shouldn’t have agreed with Smee so quickly when he asked about the valve because the 0 VAC between VCH7.1 and VCH7.3 rules out an open valve coil. If the valve coil were open and the triac was closing, then the valve is getting its supply voltage but not doing its job. Just one of those webinar things. That’s why I like people asking questions about them. Great job paying attention!

Each manufacturer does labels things differently. It helps if you understand the function of the different connections because then the differences in labelling won’t throw you. We have some manufacturer instruction sheets here at Appliantology.

Mostly very good! However…

4. If the same voltage is applied to both sides of a load it would trip the circuit breaker and it’s called a short. ( Return current has to be 0v or else it would trip the circuit breaker)

No, this is simply another way of describing a shunt. Electrically, this is exactly what a shunt does to bypass a load: applies the same voltage potential on both sides of a load. Doesn’t matter if that voltage is 120 VAC, 240 VAC, Neutral, or some DC voltage– as long as it is the same potential on either side of the load. The effect of having the same voltage potential on either side of a load means that there is no voltage difference across the load. Without a a voltage difference across a load, there’s nothing to drive electrons through the load. This is why understanding the distinction between voltage and voltage drop is so important.

Your other statement about “return current has to be 0V or else it would trip the breaker” doesn’t make sense. First of all, current is measured in amps, not volts. So that statement is conceptually incorrect.

Think about a load with a 120 VAC supply voltage. 100% of the electrons being pushed and pulled through that load by the changing Line polarity will be present in Neutral as well. If I have 50 amps being pushed through a load from the Line side, all 50 of those amps will be present on the Neutral side as well. Current (amps or electron movement) is never consumed. WATTS are “consumed” (actually, it’s more accurate to say watts are produced in loads), but not amps. So with my amp clamp, I would measure 50 amps whether I clamped it around the Line conductor or around the Neutral conductor.

Now the VOLTAGE on the Neutral in that circuit will be 0 V because Neutral is at Ground potential. Neutral could be carrying 200 amps but it’s at Ground potential (0 V with respect to ground). So if my body is at ground potential, I could grab that Neutral conductor carrying 200 amps with my bare hands and not get shocked because there’s no voltage difference between the Neutral conductor and my body to drive electrons through my body. However, if I grab the Line conductor carrying those same 200 amps, I would get electrocuted and probably die a horrible, twisted, screaming death because the Line conductor is NOT at ground potential and there is a big voltage difference between the Line conductor and my body to drive electrons through my body.

After watching the video again, my only question is that if the cold water valve were to fail instead of the drain pump, why would you measure 0 VAC between VCH7.1 to VCH7.3? I thought i should measure 120vac because the cold valve circuit is open and there should not be any voltage present at VCH7.3. I got why i should get 0VAC between VCH7.1 to VCH7.3 if the drain pump failed because now I got an open neutral but line voltage is still present at VCH7.3 all the way up to DP2.2.

Give me the time stamp on the video where you saw this so I can jump to it and review. I make so many videos, I don’t remember them all in detail and don’t have time to re-watch them in their entirety.

The schematics for washers with mechanical timers are actually trickier in many instances than the schematics for computer-controlled appliances. Similarly, old skool dryer schematics are often trickier than the schematics for computer-controlled appliances. The reason for this is that when you have distributed controls that can act independently in a washer or dryer, the engineers had to be a lot more clever with how they designed the circuitry. When you have a central computer controlling everything, you don’t need to resort to clever circuit tricks to make the machine operate the way you want.

The trickiest part with computer-controlled appliances is not the schematic– they’re often very simple– it’s knowing and understanding key operational aspects of the software controlling the computer. For example, knowing that a computer will monitor temperature input from a thermistor or pressure transducer to make decisions about which valve (hot or cold) to energize and for how long.

One of the trickiest circuits you’ll see in computer-controlled appliances that is discussed in detail in the last video in Module 3 Unit 4 is the triac-controlled loads on a Whirlpool Duet washer. But the circuit configurations shown there are nothing different from what you learned in the Core Appliance Repair Training course, for example, shunting loads when you don’t want them to run and loads in series configurations. These configurations are commonly used in old skool appliances. But this is exactly what made this schematic interesting and worth showing in the course. In fact, your question reveals that you would greatly benefit from reviewing that video. To help you with this, I have some bonus quiz questions for you below that I would like you to answer:

1. How is Line voltage supplied to the drain pump?

2. If the triac for the drain pump and the triac for the cold water valve were both closed at the same time, would the cold water valve open? Why or why not?

3. How are the triacs shown in the video controlled?

4. If the same voltage is applied to both sides of a load, would it blow the breaker? What is this called?

5. If the triac for the water valve is closed and the triac for the drain pump is open, how does the water valve get Neutral? Would the drain pump run in this situation? Why or why not?

6. In a series circuit with two loads, what is the voltage drop across the load proportional to?

7. Suppose you have two loads in series connected to a 120 VAC source. The resistance of Load 1 is 5000 ohms and the resistance of the Load 2 is 200 ohms. What are the voltage drops across the two loads? If Load 2 requires 120 VAC to operate, would it be able to operate in this configuration?

8. In the drain pump winding fails open, what problem in the washer operation are you likely to see?

9. Why would the engineers design the drain pump and water valve circuit this way?

10. What kind of meter will you use or what setting will your meter be on when you make your voltage measurements in the circuit? -

AuthorPosts